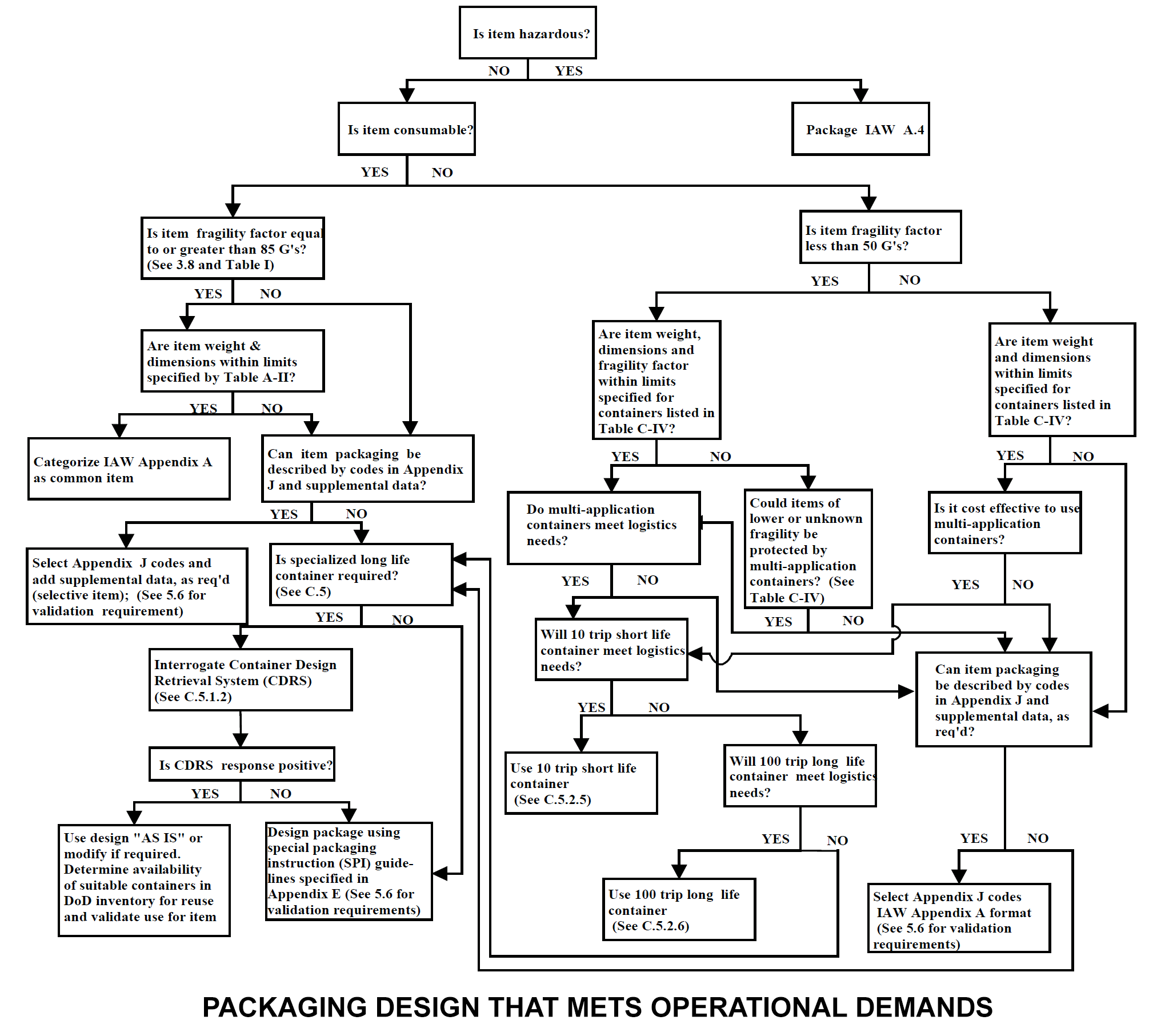

PACKAGING DESIGN THAT MEETS OPERATIONAL DEMANDS

This method outlines standard processes for the development and documentation of federal packaging. Methods of preservation to protect material against environmentally induced corrosion and deterioration, physical and mechanical damage, and other forms of degradation during storage, multiple handling, and shipment of material in the Federal Transportation System. Below is a decision table for determining how to develop federal packaging requirements. The Federal Transportation System required the following items.

- Delivered during wartime for deployment or sustainment to operational units.

- Depot level repairables.

- Requiring reusable containers.

- Intended for delivery at sea.

- Security Assistance/Foreign Military Sales/Grant Aid (unless otherwise directed by the destination country).

STEP I: FUNCTIONAL IDEAS

Packaging of an electronic system must consider protection from mechanical damage, cooling, radio frequency noise emission and electrostatic discharge. There are several factors that make crating and shipping semiconductor equipment especially challenging. Given the nature of the products, typically being shipped from a clean room environment, DESIGN AND ENGINEERING is required in order to maintain a product's integrity throughout its journey.

Factor Electronics such as tablets, computers, components and network chassis are fragile and must be protected against damage. Retail packaging is usually not enough to provide adequate protection during transit. Pack the box as tight as you can with bubble wrap, foam inserts, or tightly-wadded kraft paper. (Don't use polystyrene "packing peanuts" or other types of loose-fill packaging--they create static electricity and won't keep your device from sliding around.) Seal the box with packing tape.

- Box-in-Box Packing is suitable for fragile, small, thin and irregular-shaped articles (hard drives, memory cards, ethernet adapters, circuit boards, disk-based storage devices, laptops, monitos, tablets, destop PCs, eg). 1st, the product is packed in the original manufacturer's packaging complete with inner cushioning material. 2nd, place it in a shipping box at least 6" larger all around, use a dual-wall box for heavier items. Place 2" of filler material on the base of the shipping box before placing the shipping item inside. Ensure a gap of at least 2" is maintained on all sides before surrounding the inner box with more filler material. Fill all available space for best results. 3rd, close and seal the box with pressure sensitive tape. If shipping multiple items in a single box, ensure they are also well separated from one another.

STEP II: AESTHETIC IDEAS

Product boxes give you the freedom of designing them in any way you want. They can fully be customized on the inside and outside of the box. This gives your brand tons of creative freedom to express your story, make your products stand out, and attract more customers. Packaging directly affects brand and product perception. A good packaging design is a design that is appropriate for the company (communicating, product dentity), the product/product line (attractive) and the target customers. It's best to design packages that can live on with a secondary use.

Get the most performance out of paperboard by investing in structural design. Custom-fitting a carton to a product can reduce the amount of material while maintaining the same stacking strength. The compression performance of cartons and cases can also be important where the carton or case is required to provide some or all of the top-load strength (if the product itself is limited in how much load it can carry). A strategic approach to packaging design and development to meet customer needs, quality expectations, competitive price, reduction of product design cycle time, and minimize disuptive design changes can be effectively produced with a well planned process. If applicable, design in saving.

- Step 1: Define the Shipping, Handling, and Storage Environments. The shipping, handling and storage environments must be determined. With this information, the Preservation and Packing Levels are determined. They may be either be Military Packing Level A or Level B.

STEP III: PRODUCT REDESIGN

When we are looking to package a product, we need to decide which type of material we will package our products in. But what material should we choose? Plastic, bio-plastics, metal, cardboard, boxes, paperboard, shrink film, foil, clamshells, or something else? In order to do this, we need to understand which materials are appropriate for our applications. Below is a list of different types of packaging materials. Each material will be explored in regard to what they are made out of.

Foam Shipping Products is manufactured in buns (large blocks) or planks and may have to be cut or skived (trimmed or split to exact thicknesses) into sheets before it can be worked with. A foam packaging product has to then be custom cut and manufactured into smaller parts and often requires some assembly. There are many different fabrication technologies available depending on the shape, quantity, and quality that is required for the application, need for precision, and budget. The correct foam must support the mass load and still cushion sensitive equipment from impact forces.

- Single Face: One corrugated medium is glued to one flat sheet of linerboard; flutes exposed.

STEP IV: THE BASE

Foam Materials:

- FibreFoam. Cellulose fibers are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers. Cellulose fiber is a natural material that degrades much more quickly than synthetic materials, such as SAP and plastics. Using cellulose to replace synthetic materials can reduce the non-degradable material, such as plastic, deposited into the natural environment. Advanced cellulose films and paper can be good barriers for oxygen and carbon dioxide gases, as well as for water vapor. Several cellulose fiber-based packaging products have been commercialized in areas that used to be occupied solely by plastic products.

STEP V: THE BOX

Foam Materials:

- FibreFoam. Cellulose fibers are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers. Cellulose fiber is a natural material that degrades much more quickly than synthetic materials, such as SAP and plastics. Using cellulose to replace synthetic materials can reduce the non-degradable material, such as plastic, deposited into the natural environment. Advanced cellulose films and paper can be good barriers for oxygen and carbon dioxide gases, as well as for water vapor. Several cellulose fiber-based packaging products have been commercialized in areas that used to be occupied solely by plastic products.

STEP VI: THE TEST

Foam Materials:

- FibreFoam. Cellulose fibers are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers. Cellulose fiber is a natural material that degrades much more quickly than synthetic materials, such as SAP and plastics. Using cellulose to replace synthetic materials can reduce the non-degradable material, such as plastic, deposited into the natural environment. Advanced cellulose films and paper can be good barriers for oxygen and carbon dioxide gases, as well as for water vapor. Several cellulose fiber-based packaging products have been commercialized in areas that used to be occupied solely by plastic products.

REFERENCES AND RESOURCES

FOAMBOARDS offer the largest variety of foam board accessories including design and cutting tools, cornerforms and cornerfits, velcro products and a selection of safety straight edges, Olfa knives, Fletcher-Terry cutters, hot wire cutters and more!

IMPACT Mfg offer Plastic Based Packaging, Papper Based Packaging, Clamshell Packaging, Thermalform Trays, Flocked Trays, ESD Trays and Lids, Folding Cartons, Blister Packaging, Counter Top Display, Product Photography and more!

MPE Madison Polymeric Engineering, Inc. is a professional manufacturing company capable of providing customers with custom foam design & die cutting. Medical/Packaging Applications – Engineering Services – Design Services – Material Selections.

Nelson Container Packaging for Electronics & Corrugated Boxes for Electronics Equipment – Package Design – ISTA Testing – Protective Inner Packaging, Package Assembly and more.

NEFAB provides complete packaging solutions optimized to reduce total cost and environmental impact in your supply chain. & Packaging Solution – Packaging Products – ISTA Testing – Logistics Services and more.

Pelican Build to protect & Professional Cases – Protector Cases – Cargo Cases – Millitary, Goverment, Aviation, Aerospace and more.

Shorr Packaging Company Corrugated Products & Taps and Adhesives – Stretch Wrap Films – Protective Packaging Products – Flexible Packaging – Case Sealers – Case Erectors – Tray Formers – Baggers and Bagging Systems and many more packaging equipments.

Trans-Consolidated Distributors, Inc is one of the largest US distributors of industrial tape, stretch film, poly bags, and custom printed tapes, labels and more. We also carry 1000’s of other products to meet your packaging needs.

Zoro – Brass, Alloy Steel, Copper, Bronze – Foam and Foam Sheets, Cork, Fabric, Ceramic – Rubber, Plastics, Fiberglass, Wire Fabric, Aluminum, Stainless Steel, Carbon Steel, Shim and Shim Stock – Adhesive, Fasteners and Welding.