PACKAGING and PACKAGING MATERIAL

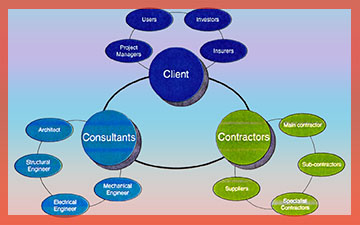

When making a purchase for packaging materials and machinery, there are 3 very important factors that we should consider: delivery, quality, and service. All of these factors should be considered when making a packaging purchase for the business that we work for. Poor customer service can end up costing company both time and money. Look for companies that have expertise in the product or service we’re interested in. Don’t choose a converter (người chuyển đổi) without knowing what you want to achieve. Don’t let design firms waste time proposing complicated designs or flashy effects (đề xuất các thiết kế phức tạp hoặc hiệu ứng hào nhoáng) that can’t be reliably or cost-effectively produced. Be aware of what custom tooling might be needed for new designs. Know your company budgetary options in metallized substrates (chất nền kim loại), holographic board (bảng ba chiều), foil-stamping (dập lá), or other effects. Consult with the retailer on their stated specs and their flexibility, and document sources, processes, safety practices, and test runs. Double-check all measurements, and make sure you’re not mixing up inside diameters and outside diameters, or heights, widths, and depths.

Reliable Vendor: Choose a company that is willing to allow its employees to be trained to your standards and certified if necessary. Select a crating and shipping company that has experience with semiconductor equipment or other high-tech equipment like robotics, complex medical devices or optics where unique packaging solutions are required. A solid packaging company should be able to evaluate your designs (đánh giá thiết kế của bạn), point out flaws (chỉ ra những sai sót), suggest alternatives and substitute materials when appropriate. In selecting a packaging company for semiconductor equipment, your goal is to achieve customized solutions that meet your exact requirements. Make certain that the vendor has knowledge of labeling and documentation requirements specific to your destinations. Are ISO certifications required? Excess moisture (Độ ẩm quá mức), temperature and vibration can damage electronic device and bring down company reputation. Be sure to inquire about the methods employed to reduce shipping hazards (giảm những rủi ro khi vận chuyển) and be certain they meet your standards. Can the crating and shipping company engineer and design packaging that is easy to load and unload?

Delivery On Time: (Giao hàng đúng hạn) Reliable supplier/vendor/manufacturer – Overnight/Expedited Shipments – Receiving Time Consistency – Orders Properly Package for Shipping – Customer Services Quality – Order Specification Confirmation – Online Rating – References.

SPONSORED CONTENT

Your Service Flyer

Your Event Invitation

Your Promotion Ads

Your Logo & Brand

Support us and grow your business with us. My goal was to make technical information available with ready access to commonly needed resources, formulas, and reference materials while performing my work as a Technical Support Engineer. The businesses listed in Sponsored Content section were randomly selected because of their uniqueness. However, non-sponsored selected ads wil be rotated monthly.

Viba Direct lacks an advisory board to do research and hire writers with the latest technological knowledge. Creating an effective advisory board requires more than an invitation. Without your sponsorship, this is not possible. If your company is interested in placing the company's logo, brand, eventinvitation, and otherpromotional banners and flyers here or on any other pages. Please reach out to Customer Service for more detail.

Order Confirmation Email from supplier should includes: Order Number – Customer Contact Details – Shipping Address – Order Summary – Cost Break Down in Details – Payment Method and Amount – Shipping Method – Return Policy (if you order the wrong item or if your customer cancelled their order with you).

Customer Service Quality: (Chất lượng dịch vụ khách hàng) Problems and Emergencies Responding – Sale Representative Service Consistency (to improve every aspect of company account) – Fast and Accurate Quote (How long does it take to receive a request for a quote?).

Price: Supplier's Price Competitive – Payment Terms Offer (Standard terms are net 30 but why not ask for something better?) – Cost Reduction Commitment (f you order a larger quantity or if there are any special rebates or incentives currently available) – Price Awareness (Ensure the buyer is aware of the price increase before announcing it).

Perform Extensive Testing: (Thực hiện kiểm tra sâu rộng) Use approved board, and don’t make hasty decisions. Look into independent crush-strength or durability testing by external labs, ASTM or ISTA certifiers, or company standards. Beware of management pushing through a decision before proper testing. Guard against print-tone deviations by getting approved processes and samples—and document the results. Monitor suppliers regularly to verify what they are supplying. A slight process change can affect the performance or appearance of a package. Look closely at the traceability of the paperboard source materials. Is it certified by a third party? Have you looked at all the components that go into the board? Get the documentation that backs up the product claims.

ELECTRONICS and SEMICONDUCTOR DEVICES PACKAGING

Packaging of an electronic system must consider protection from mechanical damage, cooling, radio frequency noise emission and electrostatic discharge (phát xạ tiếng ồn tần số vô tuyến và phóng xả tĩnh điện) Use approved board, and don’t make hasty decisions. Look into independent crush-strength or durability testing. There are several factors that make crating and shipping semiconductor equipment especially challenging. Given the nature of the products, typically being shipped from a clean room environment, DESIGN AND ENGINEERING is required in order to maintain a product's integrity (tính toàn vẹn của sản phẩm) throughout its journey.

Electronics Packaging main demand is for the package to not accidentally damage the product inside with unintended electrical charges from static electricity produced by friction (tích điện ngoài ý muốn từ tĩnh điện sinh ra do ma sát). This means a primary package that has electro static barrier (rào cản tĩnh điện), static-dissipative materials or static-shielding (vật liệu chống tĩnh điện hoặc vật liệu che chắn tĩnh điện). Basically these are always plastics with functional properties, but secondary packaging may be strong carton boards that have moisture barrier (rào cản độ ẩm), because moisture may influence how well the secondary packaging works. The secondary package also has to protect the possibly fragile electronic device from physical damage, so carton boards are well suited for the task.

How do you pack electronics for shipping? Electronics such as tablets, computers, components and network chassis are fragile and must be protected against damage. Retail packaging is usually not enough to provide adequate protection during transit (cung cấp đầy đủ bảo vệ trong quá trình vận chuyển). Pack the box as tight as you can with bubble wrap, foam inserts, or tightly-wadded kraft paper. (Don't use polystyrene "packing peanuts" or other types of loose-fill packaging, they create static electricity and won't keep your device from sliding around). Seal the box with packing tape.

Box-in-Box Packing is suitable for fragile, small, thin and irregular-shaped articles (hard drives, memory cards, ethernet adapters, circuit boards, disk-based storage devices, laptops, monitors, tablets, desktops PCs, e.g.). 1st, the product is packed in the original manufacturer's packaging complete with inner cushioning material. 2nd, place it in a shipping box at least 6" larger all around, use a dual-wall box for heavier items. Place 2" of filler material on the base of the shipping box before placing the shipping item inside. Ensure a gap of at least 2" is maintained on all sides before surrounding the inner box with more filler material. Fill all available space for best results. 3rd, close and seal the box with pressure sensitive tape. If shipping multiple items in a single box, ensure they are also well separated from one another.

BOXES and PACKAGING DESIGN

Focusing on the packaging design can make advertising more effective, satisfy customer purchase, and easier to ship. The primary purpose of packaging is to protect its contents from any damage that could happen during transport, handling and storage. Packaging retains the product intact throughout its logistics chain from manufacturer to the end user (Bao bì giữ sản phẩm nguyên vẹn trong suốt chuỗi hậu cần của nó từ nhà sản xuất đến người dùng cuối cùng). Product packaging reflects quality, when it comes to what's important for overall satisfaction with a product, consumers rank packaging almost equal to the brand. Packaging design involves the design and creation of a product's container and how it looks to consumers who might purchase it. Packaging must be sturdy and reliable to protect the product inside. Also, they must meet the needs of society in a sustainable by minimizing product waste, improving the quality of life, protecting the environment, managing packaging waste through recovery and recycling. If applicable, design in saving.

*Hậu cần. Hoạt động chuyên chở, lưu giữ và cung cấp hàng hóa. Trong sản xuất kinh doanh, đây là nghệ thuật và khoa học của quản lý và điều chỉnh hệ thống di chuyển của hàng hóa, năng lượng, thông tin và những nguồn lực khác như sản phẩm, dịch vụ và con người, từ nguồn lực của sản xuất cho đến thị trường. Thật là khó khi phải hoàn thành việc tiếp thị hay sản xuất mà không có sự hỗ trợ của hậu cần. Hậu cần thể hiện sự hợp nhất của thông tin liên lạc, vận tải, tồn kho, lưu kho, giao nhận nguyên vật liệu, bao bì đóng gói. Trách nhiệm vận hành của hoạt động hậu cần là việc tái định vị (theo mục tiêu địa lý) của nguyên vật liệu thô, của công việc trong toàn quá trình, và tồn kho theo yêu cầu chi phí tối thiểu có thể. Và di chuyển thành phần đến nơi tiêu thụ sau quá trình sản xuất. Xem tường tận hơn ở đây...

NỘI DUNG TÀI TRỢ

Quảng Cáo Dịch Vụ

Quảng Cáo Sự Kiện

Quảng Cáo Khuyến Mãi

Biểu Trưng & Nhãn hiệu

Hỗ trợ chúng tôi và phát triển doanh nghiệp của bạn với chúng tôi. Mục tiêu của tôi là cung cấp thông tin kỹ thuật với khả năng truy cập sẵn sàng vào các tài nguyên, công thức và tài liệu tham khảo thường cần thiết trong khi thực hiện công việc của mình với tư cách là Kỹ sư hỗ trợ kỹ thuật. Các doanh nghiệp được liệt kê trong Nội dung được Tài trợ đã được lựa chọn cẩn thận vì tính độc đáo của chúng. Tuy nhiên, các quảng cáo liệt kê không được tài trợ sẽ được luân chuyển thay đổi hàng tháng.

ViBa Direct thiếu một ban cố vấn để thực hiện nghiên cứu và thuê các nhà văn với kiến thức kỹ thuật hiện đại. Việc tạo ra một ban cố vấn hiệu quả đòi hỏi nhiều hơn là một lời mời. Nếu không có sự tài trợ của bạn, điều này khó có thể thực hiện. Nếu công ty của bạn có nhu cầu quảng cáo, đặt biểu trưng, thương hiệu, biểu ngữ mời tham gia thảnh viên, hội viên cũng như các bích chương quảng cáo ở đây hoặc trên bất kỳ trang nào khác, xin vui lòng liên hệ với nhóm Dịch Vụ Khách Hàng để biết thêm chi tiết.

Product boxes give you the freedom of designing them in any way you want. They can fully be customized on the inside and outside of the box. This gives your brand hundreds of creative freedom to express your story, make your products stand out, and attract more customers. Packaging directly affects brand and product perception (Bao bì ảnh hưởng trực tiếp đến thương hiệu và cảm nhận về sản phẩm). A good packaging design is a design that is appropriate for the company (communicating, product identity), the product/product line (attractive) and the target customers. It's best to design packages that can live on with a secondary use.

PACKAGING THAT MEETS OPERATIONAL DEMANDS

Functional Ideas (Ý tưởng chức năng): Define the Shipping, Handling, and Storage Environments. The shipping, handling and storage environments must be determined. With this information, the Preservation and Packing Levels are determined. They may be either be Military Packing Level A or Level B.

Aesthetic Ideas and Product Characteristics (Ý tưởng thẩm mỹ và đặc điểm của sản phẩm). Determine Item Characteristics. Determine dimensions, weight, fragility rating, number of items to be shipped, and any other special considerations.

Product Development and Redesign (Phát triển và thiết kế lại sản phẩm). The weakest elements of the item may be modified to improve its durability. This can usually be done inexpensively if done during the item's design process. After redesign the item characteristics in functional ideas are recalculated.

The Base or Cushioning System (Hệ chân đế hoặc đệm): Choosing the proper cushioning material and designing its configuration requires a knowledge of both item characteristics (product characteristics) and drop height determined from the Packing Level in functional ideas and the weight from product characteristics.

The Box or The Package System (Hộp hoặc Hệ thống đống gói). The inner size of the container is determined from the size of the item plus its cushioning. The container can be made of a variety of materials. The package designer chooses the one that fits best with the packing level determined in functional ideas.

Drop, Shock Survivability and Reliability Test (Kiểm tra và thử nghiệm độ rơi, khả năng không vỡ sau khi va chạm). The prototype container is subjected to shock and vibration tests. Test levels are derived from the packing level determination in functional ideas (Các cấp độ thử nghiệm được rút ra từ các ý tưởng chức năng trong việc xác định cấp độ đóng gói).

PACKAGING FUNCTIONS: (Chức năng đóng gói) Contain the product – Carry – Protect goods from mechanical damage – Dispense products – Preserve products from deterioration – Measure – Communicate between the customer/consumer and producer – Retail and point of purchase displays – Brand – Build Up Contents – Disguise – Promote – Innovate.

PROTECTIVE PACKAGING: Molded cases – Die cut cases – Soft cases – Fabricated cases – Wood boxes – Corrugated boxes.

PACKAGING DISTRIBUTION SYSTEM: Production —» Warehouse —» Local Distributor —» Long Haul —» Wholesaler —» Retailer —» Consumer.

SEMICONDUCTOR EQUIPMENT CRATES: Shock Mount and Vibration Protective Bases – Wood Crates – Corrugated Boxes – Wood and Corrugated Combo – Heavy Duty Skids – Corrugated boxes.

TYPICAL BOXES and CONTAINERS

Corrugated Boxes (Hộp, thùng carton) are often used for packaging applications in tandem with case erectors. Case erectors are a type of packaging machinery that involves human labor and automated processes to form, fill, and seal the boxes in preparation for shipping.

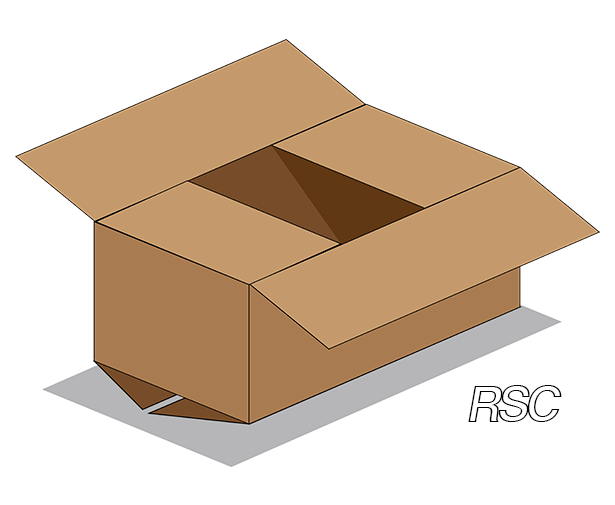

Regular Slotted Container (RSC):

Slotted box styles are generally made from one piece of corrugated or solid fiberboard. The blank is scored and slotted to permit folding. The box manufacturer forms a joint at the point where one side panel and one end panel are brought together. Boxes are then shipped flat to the user. When the box is needed, the box user squares up the box, inserts product and closes the flaps. Regular Slotted Container's flaps all have the same length, and the two outer flaps are one-half the container's width, so that they meet at the center of the box when folded.

Slotted box styles are generally made from one piece of corrugated or solid fiberboard. The blank is scored and slotted to permit folding. The box manufacturer forms a joint at the point where one side panel and one end panel are brought together. Boxes are then shipped flat to the user. When the box is needed, the box user squares up the box, inserts product and closes the flaps. Regular Slotted Container's flaps all have the same length, and the two outer flaps are one-half the container's width, so that they meet at the center of the box when folded.

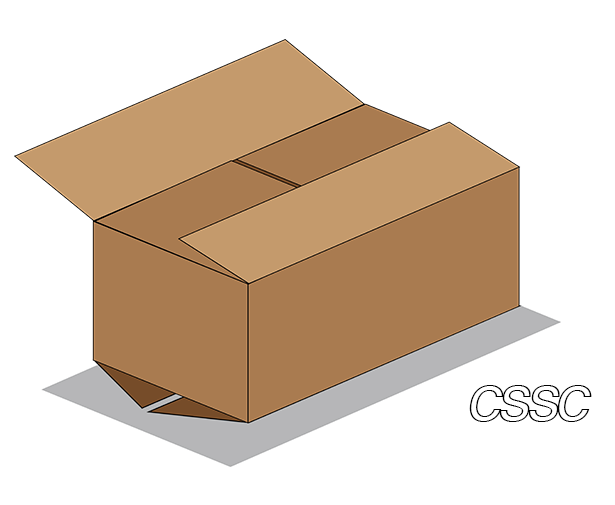

Center Special Slotted Container (CSSC): Same as RSC but inner and outer flaps are cut to different lengths. When closed, the inner flaps meet at the center of the box, and outer flaps fully overlap. With three full layers of combined board over the entire top and bottom,

this style provides extra cushioning when stacked on its bottom, or extra stacking strength when stacked on its side.

this style provides extra cushioning when stacked on its bottom, or extra stacking strength when stacked on its side.

Full Overlap Slotted Container (FOL): This box is used when the length of the box is considerably greater than the width, resulting in a long gap between the inner flaps. The sealed overlap helps to keep the outer flaps from pulling apart. All flaps have the same length (the width of the box). When closed, the outer flaps come within one inch of complete overlap. The style is especially resistant to rough handling. Stacked on its bottom panel, the overlapping flaps provide added cushioning. Stacked on its side, the extra thickness provides added stacking strength.

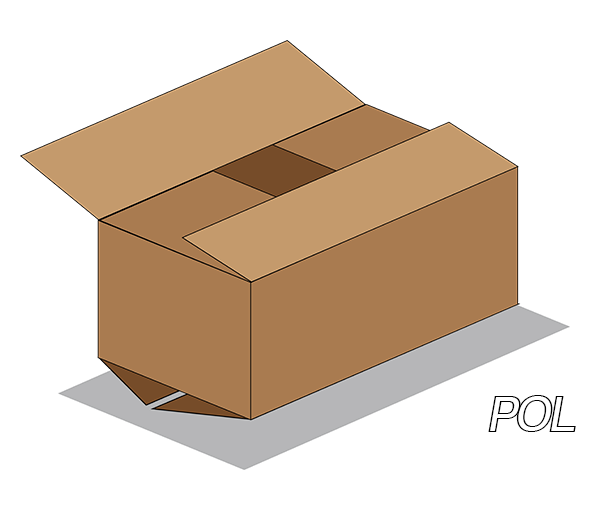

Partial Overlap Slotted Container (POL) is as same as RSC with all flaps have the same length. The outer flaps overlap by one inch or more. The box is easily closed, usually with staples driven through the overlap area. This style is used when the length of the box is considerably greater than the width, resulting in a long gap between the inner flaps. The sealed overlap helps to keep the outer flaps from pulling apart.

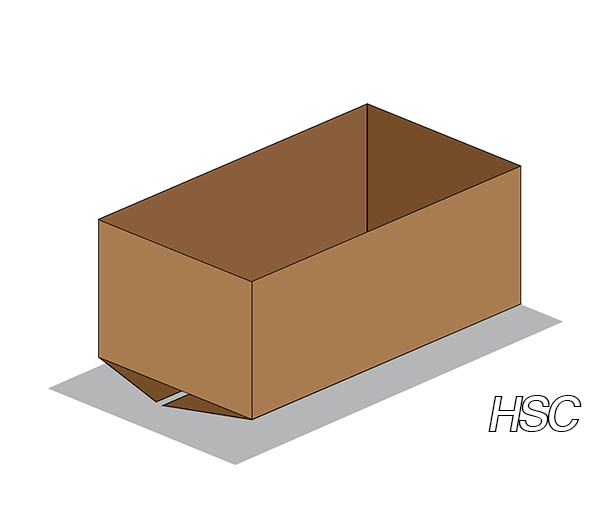

Half Slotted Container (HSC) is as same as RSC without one set of flaps.

Roll End Tuck Top Container (RETT) is an unglued box that needs to be folded when assembled. The sides are 3 layers of custom corrugated for added strength and the top opens and closes with a tuck to the inside of the box. You can also add dust flaps and cherry locks for added stability.

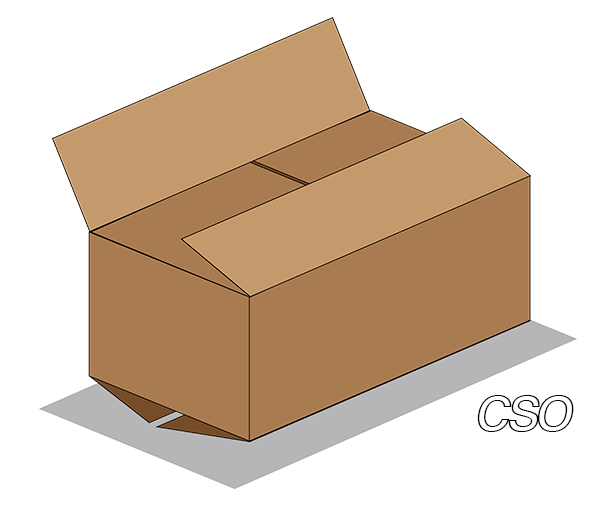

Center Special Overlap Slotted Container (CSO) Same as RSC except all flaps have the same length (one-half the length of the box).

Snap Bottom Container with Tuck Top (SBCTT): The four flaps that form the bottom panel are die cut. The length of the box can be no more than twice its width. To set up, the user folds the largest bottom panel first, then the two end panels. When the remaining bottom panel is folded and pressure is applied near the center, the flap "snaps" into the slot created by the other panels. The style is convenient for small-volume shippers who do not have automatic set-up equipment. Because the bottom is not fully sealed, it may not be suitable for heavy products.

Snap Bottom Container with RSC Top (SBCRSCT):

Same as SBCTT, replacing the tuck top configuration with RSC style flaps.

Same as SBCTT, replacing the tuck top configuration with RSC style flaps.

Full Bottom File Box: Designed to provide an interlocking thickness on its bottom and on its end panels.

Box Dimensions: Dimensions are given in the sequence of length, width and depth. Internationally, the words length, breadth, and height may be used to express these dimensions. The dimensions of a box are described based on the opening of an assembled box, which can be located on the top or the side, depending on how it is to be filled. The opening of a box is a rectangle; that is, it has two sets of parallel sides. The longer of the two sides is considered its length, the shorter of the two sides is considered its width. The side perpendicular to length and width is considered the depth of the box. Dimensions can be specified for either the inside or the outside of the box. Accurate inside dimensions must be determined to ensure the proper fit for the product being shipped or stored. At the same time, palletizing and distributing the boxes depends on the The box manufacturer should be informed as to which dimension is most important to the purchaser/company. outside dimensions.

- VOLUME = LENGTH x WIDTH x HEIGHT / 10.2 x 10.1 x 5.38 = 554.25 in³

To determine the proper length, width and depth of an existing structure, place the carton facing you with the opening up. Dimensions should be measured from the center of score to center of score (trung tâm của vết cắt hoặc đường rạch đến trung tâm của vết cắt), and given to the nearest sixteenth of an inch. Always refer to the outside dimensions of the carton.

Corrugated Boxes Folding: Score to Score (Dimension) – Score to Score (Dimension).

Corrugated Boxes Joining: Taped Joint – Glued Joint – Stiched Joint.

Folding Carton (common styles): Reverse Tuck (gài ngược) – Airplane Style – Seal End – Auto-Lock Bottom – Straight Tuck (gài thẳng) – Hardware Bottom – Mailing Lock – Cracker Style – Breakawy Flip Top – Hardware Bottom Ice Cream – Hardware Bottom Reclosable Seal End – Hardware Bottom Seal End with Van Buren Ears.

Kraft Paper Packaging (folding carton): Kraft paper packaging is becoming a popular material for folding carton product packaging. With its super strength and eco-friendly nature, it has become an effective marketing tool for product marketers.

Folding Cartons Manufacturing Rules: Creasing – Cutting – Thickness. Avoid extra flaps and use multiple printing methods tochieve high-quality perceptions. If hand-loading, use an auto-lock bottom for most efficient lines.

Non-Folding Boxes: Throwaway Box — Full Telescope — Extension Edge with Padded Cover — Tube and Slide — Necked Box with Hinged Cover.

Non-Folding Boxes Setup: Base (Wrapper + Stripped Neck with Turn In + Die Cut Platform + Collar) —» Finished Box (Base + Hinge + Ribbon Support + Wrapper + Stay Lid).

PACKAGING MATERIALS AND THE DIFFERENT

When we are looking to package a product, we need to decide which type of material we will package our products in. But what material should we choose? Plastic, bio-plastics, metal, cardboard, boxes, paperboard, shrink film, foil, clamshells, or something else? In order to do this, we need to understand which materials are appropriate for our applications. Below is a list of different types of packaging materials. Each material will be explored in regard to what they are made out of.

Foam Shipping Products (sản phẩm vận chuyển cao su xốp) is manufactured in buns (large blocks) or planks and may have to be cut or skived (trimmed or split to exact thicknesses) into sheets before it can be worked with. A foam packaging product has to then be custom cut and manufactured into smaller parts and often requires some assembly. There are many different fabrication technologies available depending on the shape, quantity, and quality that is required for the application, need for precision, and budget. The correct foam must support the mass load and still cushion sensitive equipment from impact forces.

Wood Shipping Crates (Thùng vận chuyển bằng gỗ) are designed to transport or store heavy items. It has a self supporting structure, with or without sheathing. This makes wooden crates much stronger and more supportive than merely a wooden box. Products sensitive to shock and vibration require special protection in shipping, both to secure it in place while shipping, and also to mitigate the damaging effects of supply chain handling, warehousing and transportation via truck, rail and air. Wood crates are specially designs and manufactures for the size, weight, shape, fragility, sensitivity, and destination of the item to be shipped with ASTM Specs. Unique products require unique packaging designed for specialized material handling, loading and unloading, blocking and bracing, and shock and vibration protection requirements. Most of today wooden shipping crates are ISPM-15 compliant, heat treated and appropriately marked for export.

It has a self supporting structure, with or without sheathing. This makes wooden crates much stronger and more supportive than merely a wooden box. Products sensitive to shock and vibration require special protection in shipping, both to secure it in place while shipping, and also to mitigate the damaging effects of supply chain handling, warehousing and transportation via truck, rail and air. Wood crates are specially designs and manufactures for the size, weight, shape, fragility, sensitivity, and destination of the item to be shipped with ASTM Specs. Unique products require unique packaging designed for specialized material handling, loading and unloading, blocking and bracing, and shock and vibration protection requirements. Most of today wooden shipping crates are ISPM-15 compliant, heat treated and appropriately marked for export.

Plastic Cases (hộp nhựa) is made from high impact Acrylonitrile-butadiene styrene (ABS) plastic. They are designed to protect and move high value, sensitive, and delicate equipment and instruments that will be routinely and repetitively transported to trade shows, customer demos, sales presentations/ events, customer training, music or sporting events, or for field repair.

Clamshell (hộp đựng khung sườn) containers can be made of a variety of plastics such as polystyrene, polyester, PVC, foam sheets, etc. The material can be made by thermoforming (tạo hình bằng nhiệt) or can be injection molded (tạo hình bằng ép đúc khuôn) into the desired box-shaped containers with a hinged lid and closures, which can be made re-closable or permanently sealed with theft deterrence. With clamshell plastic packaging, the product is protected from poor storage conditions and improper handling during transport. Clamshell plastic packaging securely seals the product from airborne contaminants, protecting its safety and freshness.

Corrugated Cardboard is a packaging material made out of a corrugated sheet of fiberboard that has been fluted (giấy đã được làm phẳng bằng giấy bồi có sóng được dán lại với nhau) . Corrugated cardboard is made from one or multiple boards of flat fiberboard. Corrugated cardboard is created via a process called fluted lamination (better known as: corrugation).

Corrugated fiberboard, or combined board, has two main components: the linerboard and medium. Both are made of a special kind of heavy paper called containerboard. Linerboard is the flat facing that adheres to the medium. The medium is the wavy, fluted paper in between the liners. The term "cardboard box" is commonly misused when referring to a corrugated box. Cardboard boxes are really chipboard boxes, and used primarily for lightweight products, such as cereal or board games. Corrugated fiberboard is comprised of linerboard and heavy paper medium. Linerboard is the flat, outer surface that adheres to the medium. The medium is the wavy, fluted paper between the liners. Both are made of a special kind of heavy paper called containerboard. Board strength will vary depending on the various linerboard and medium combinations.

Corrugated fiberboard, or combined board, has two main components: the linerboard and medium. Both are made of a special kind of heavy paper called containerboard. Linerboard is the flat facing that adheres to the medium. The medium is the wavy, fluted paper in between the liners. The term "cardboard box" is commonly misused when referring to a corrugated box. Cardboard boxes are really chipboard boxes, and used primarily for lightweight products, such as cereal or board games. Corrugated fiberboard is comprised of linerboard and heavy paper medium. Linerboard is the flat, outer surface that adheres to the medium. The medium is the wavy, fluted paper between the liners. Both are made of a special kind of heavy paper called containerboard. Board strength will vary depending on the various linerboard and medium combinations.

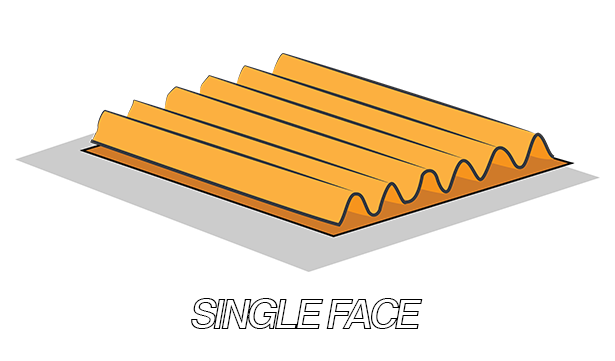

Single Face: One corrugated medium is glued to one flat sheet of linerboard; flutes exposed.

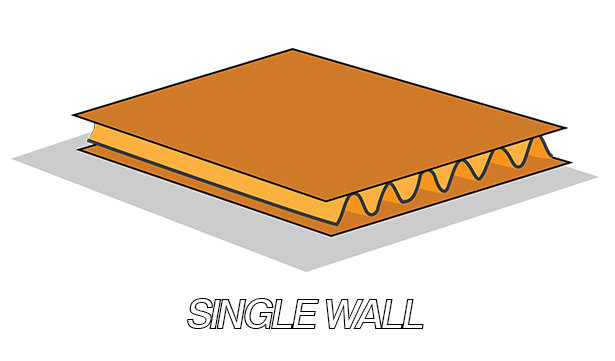

Single Wall: The corrugated medium is glued between two sheets of linerboard. Also known as doubleface.

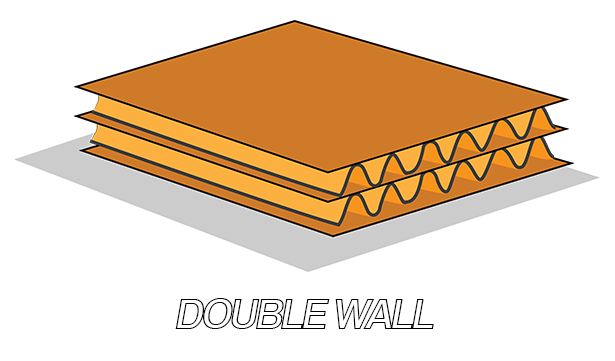

Double Wall: Three sheets of linerboard with two mediums in between.

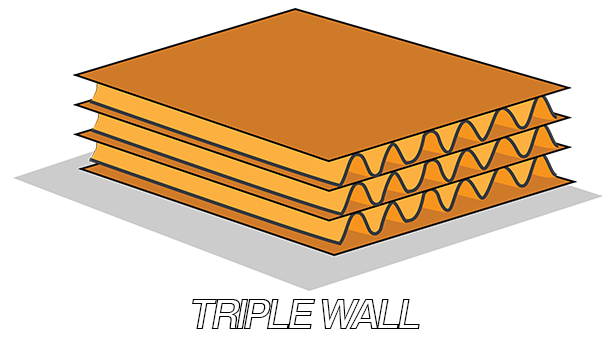

Triple Wall: Four sheets of linerboard with three mediums in between.

Corrugated board can be created with several different flute profiles. Generally, larger flute profiles deliver greater vertical compression strength and cushioning. Smaller flute profiles provide enhanced structural and graphics capabilities for use in retail packaging.

Folding Carton (Thùng gấp). A folding carton is a product container of varying sizes and shapes, typically made from paperboard. The paperboard can be printed with artwork and graphics, then die cut, creased, folded and glued. The finished product usually ships to the customer flat, where they fill it with product for distribution. Folding Cartons can range from the simplest all-paperboard carton printed with company and product info, to dramatic, dynamic cartons with intense graphics, interior structures and cello windows. Folding cartons are the lightest in weight compared to most other forms of packaging. The printed paperboard folding carton is the most common form of a box, that holds a packaged product whose primary purposes is to promote, protect and display the merchandise.

Folding Boxboard (FBB) (Hộp gấp) is a versatile packaging material used for many packaging solutions and even for some non-packaging products like cosmetics, cigarettes, pharmaceuticals, and book covers or post cards. FBB is a layered product and uses different types of pulps in different parts of the layered structure. Outer layer consists of bleached wood-free pulps and the middle ply may be any type of mechanical pulp like TMP or CTMP, so that the final product has the necessary stiffness and bulk.

White Lined Chipboard (WLC) is used for non-demanding food packaging and in the case of food products. It is usually used as secondary packaging with a plastic primary package. WLC is usually made of four layers with the goal to keep costs low, but printability in the top ply good.

SPONSORED CONTENT

Your Service Flyer

Your Event Invitation

Your Promotion Ads

Your Logo & Brand

Solid Bleached Board (SBS) is used for odor and taint free packaging. Solid Bleached Board usually consists completely of bleached chemical pulps or sometimes has a layer of CTMP, but its uses include high quality products that are sensitive to contaminants like cheese, cigarettes and chocolate.

Solid Unbleached Sulfate Board (SUS) is sometimes also referred to as Coated Natural Kraft (CNK), when produced as a single layer product. Like most cartonboards SUS also comes as a plied product. A typical grade has two or three layers and is coated. Printing properties are of consideration, but the more important qualities are stiffness and strength properties, since SUS packages usually serve as beverage carriers, which need to be able to take stress (high strength) from heavy products.

Liquid Packaging Board (LPB) is used for packaging of various liquids, mostly milks and juices but share a host of properties and demands in common. The amount of plies varies, but the original LPB type cartonboard had only two plies and may even be over 4 plies if requires. The most important factor in LPB is purity and this disqualifies non-woodfree pulps and secondary fibers. To promote barrier properties LPB is always extrusion coated or metalized, but not always pigment coated. Common important properties include purity, cleanliness and stiffness, which can be hard to achieve with chemical pulps, but essential in order to stack the packaged products for transfer and shelving.

FILM AND ITS APPLICATIONS

Stretch Film is one of the most common packaging materials in the world. Companies that have a shipping department with a warehouse are almost always using stretch film to contain their products on pallets before shipping. Load containment is achieved with stretch film to protect products from collapse or damage during the shipping process. Below is the list of available stretch film material.

- Cast Stretch Film, also known as cast stretch wrap is created by feeding a sheet of heated resin along with a rolling path with chilled rollers. The cooling solidifies the film, and it is made into large rolls. It's available in Hand Length and Machine Length.

- Blown Stretch Film, also known as blown stretch wrap, is created by blowing heated resin out vertically into a bubble. The bubble is then transformed into rolls while it is cooled by the surrounding air.

- Pre-Stretch Film is the process that allows stretch film to be stretched before (pre) being applied to a load. The film threads past two rollers (Primary and Secondary) in which the second rollers' rotational speed is faster than the first, thus stretching the stretch film between the two.

- UVI Stretch Film is the process that allows stretch film to be stretched before (pre) being applied to a load. The film threads past two rollers (Primary and Secondary) in which the second rollers' rotational speed is faster than the first, thus stretching the stretch film between the two.

- VCI Stretch Film is used to tightly bundle items such as pallets. It is like cling wrap and is tacky and adheres to itself. It is water resistant but is not the best choice for sealing out water. It is made in relatively thin mils and usually applied in multiple layers to create a secure slightly springy package.

- Vented Stretch Film is a traditional 80 gauge stretch film with die-cut holes cut approximately one-half inch apart. The holes allow moisture and condensation to escape the load after being wrapped. The vented film offers an excellent stretch rate and hold. Reinforced edges provide extra durability and strength.

- Reinforced Stretch Film is a thick films with especially strong formulations which is used to package and protect extremely heavy loads for transportation and shipping. Generally speaking, this type of film is commonly used for the palletizing and unitizing of bricks and cinder blocks.

- No Cling Stretch Film is used for packaging products such as carpeting so that the products being packaged can slide on and over each other without getting caught and tearing. There is also a variant of no cling stretch film that has only one side that clings called one-sided cling stretch film.

- Shrink Film is one of the most popular types of packaging materials currently on the market. Shrink film is commonly used to packaged items such as board games, frozen pizza boxes, and small consumer goods. There are different types of shrink film formulations. Still, the most common formulations are polyvinyl chloride (PVC), polyethylene (PE), and polyolefin (POF). Each formulation is designed for specific applications. Polyolefin is the best shrink film to wrap food with.

- Bundling Film is a type of shrink film. The formation of multi-packs (also known as shrink bundling) is the act of creating one or multiple packs (also known as bundles) out of various products or items. A multi-pack can include items that are free-standing or sitting on top of a platform or sheet of material.

- Shrink Bands, also known as seal bands. They are kind of protective packaging and tamper-evident packaging that is perforated for ease of use. Shrink bands are pre-made to fit the cap of different types of items, including but not limited to: bottles, jars, liquid-droppers, and other similar products. Shrink bands provide extra strength for the seal of the product cap. This ensures that the overall seal of the product is enhanced with additional protective qualities.

- Flexible Pounches are foil or plastic bags. They are utilized in packaging applications for various uses, including snack food packaging and industrial liquid packaging. They can be found on shelves in supermarkets practically everywhere. Flexible pounches pouches are resealable, have a low environmental impact, and are less costly to produce than alternative packaging materials such as glass, paperboard, metal, and cardboard containers.

FOAM AND ITS APPLICATIONS

Foam (Cao su xốp) can be designed, cut, and fabricated to hold any shape. Many products have protrusions like flanges, brackets and buttons that change the overall surface of the product or have varying degrees of fragility or ability to bear weight, all of which can be accommodated with a foam packaging design.

Foam Materials:

- FibreFoam. Cellulose fibers are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers. Cellulose fiber is a natural material that degrades much more quickly than synthetic materials, such as SAP and plastics. Using cellulose to replace synthetic materials can reduce the non-degradable material, such as plastic, deposited into the natural environment. Advanced cellulose films and paper can be good barriers for oxygen and carbon dioxide gases, as well as for water vapor. Several cellulose fiber-based packaging products have been commercialized in areas that used to be occupied solely by plastic products.

- Polyurethane (PU) foam produces cushioning packaging to protect light to medium heavy products throughout the shipping cycle. Polyurethane foam is excellent for protecting glass products, sensitive electronic products which are bagged, and medical post op foam positioners and immobilizers. Polyurethane foams are characterized by an open cell construction and have a softer feel, especially in the lower density and firmness ranges. They are most often the material of choice for smaller, lighter, and more shock-sensitive products. Foam density is expressed as the weight per cubic foot of material. Firmness is expressed numerically as IFD (indentation force deflection), and is completely independent of density. Polyurethane foam available in anti-static or static dissipative.

- Polyethylene (PE) foam produces end caps to support products in a carton during the shipping cycle, custom case inserts for drones and other electronic devices. End caps and protective pads made from PE can be repeatedly deflected, and will return to their original shape with little or no reduction in protective performance. Cross-linked PE can be used for pool toys, medical products which must be closed cell to prevent bacteria and foreign objects from getting embedded in the foam. Extruded or laminated Polyethylene foams are extremely tough and resilient. PE also performs well on both chemical resistance and low moisture absorption. PE foam available in anti-static or static dissipative.

- Polyeter (PL) foam offers high mechanical strength and regular & fine cell structure. Polyester foams are similar to polyurethane foams in appearance, range of densities and firmnesses (IFDs). Polyesters, however, are more resistant to hydrocarbons or alcohols, and are often specified in applications that call for a higher degree of chemical resistance. They are not affected by petroleum products or any other organic solvent. Due to their unmatched quality these are excessively used for protective packaging and packaging interlining.

- Cross-Linked Polyethylene (XLPE) foam is a high density, closed-cell foam characterized by a compact feel and its resistance to water and chemicals. The cross-linking of polyethylene is a chemical or irradiation process that ties all of the polymer molecules together with a stronger chemical bond. XLPE foam is used to protect class "A" surfaces due to its non-abrasive properties. XLPE foam is used extensively in the packaging of medical products and equipment because it generates very limited particulate.

It's also often used in multi-part presentation kits because of the materials high-end look and feel. Most PU and PE and some XLPE foams are available in anti-static formulations.

It's also often used in multi-part presentation kits because of the materials high-end look and feel. Most PU and PE and some XLPE foams are available in anti-static formulations. - Expanded Polyethylene (EPE) & Expanded Polypropylene (EPP) foam or beaded foam is produced by “popping” or expanding small beads of polymer and fusing them together with temperature and pressure into a mold. These foams also have very low compressive creep, and will return to their original shape after continuous loading. Both EPE and EPP are used extensively in automotive and packaging applications where durability, multiple impact resistance and other demanding performance challenges must be met. EPE is safe for class A surfaces.

Cut-to-size pads or bars can be used as a single layer inside a rectangular cavity such as a box, crate or molded case. In addition to protection, they can provide organization, blocking and bracing, and thermal insulation. Pads and bars are also used in many crates and crating applications.

Cut to shape or cavity cut (Die-cut, dieless cut (flash/CNC knife), water jet, profile/contour cut, or routed).

Foam end caps, or top and bottom frames are made out of PE that are accurately manufactured to support the product by encapsulating (đống nắp) the two ends with the protective foam. This concept provides maximum protection of any end cap design. The Foam end caps are then placed on the ends of the product which are placed in a corrugated box. The empty space in between the product, box, and foam, which is called an Air Cell, then gives the product ample space to move while the Protective Foam compresses and absorbs all the shock while being in transit. There are three commonly manufactured kinds of Foam End Caps that are used depending on the product, the material, and the protective requirement.  The Traditional End Cap set that is used for heavier, more valuable items where protection needs to be at maximum, the Ribbed End Cap set that relies on sufficient space to effectively protect the product, and the Hinge Lock End Cap Set where it is considered to be the most innovative for its design and cost-efficiency while providing the maximum protection among the three kinds.

The Traditional End Cap set that is used for heavier, more valuable items where protection needs to be at maximum, the Ribbed End Cap set that relies on sufficient space to effectively protect the product, and the Hinge Lock End Cap Set where it is considered to be the most innovative for its design and cost-efficiency while providing the maximum protection among the three kinds.

Adhesive-bonded foam assemblies are made out of Self Adhesive Foam Board or Heat Activated Foam Board. Self-Adhesive Foam Board is the perfect choice when cold mounting photos and artwork on to foam board. This foam board features acid-free adhesive and is chemically inert. This foam board can be supplied as 1 or 2 sided pressure sensitive. Heat Activated (HA) foamboard features an extruded polystyrene foamboard with clay coated liners, one of which is a smooth clay-coated paper on one side and neutral pH heat activated (HA) adhesive on the other. Heat activated foamboards are designed for use in mechanical and hot vacuum presses as well as heated roll laminators. Since InSite® HA board comes with a layer of smooth, evenly applied adhesive coating it is ready to use out of the case by eliminating the need for rolled mounting tissues or films. This saves both production time and money, whether a single custom mount or large production operation.

Foam Insert or a custom case insert can protect and display delicate and valuable equipment. It also presents the product in a clean, professional way that packing peanuts and bubble wrap don't offer. It's ideal for a sales presentation case or a case for a finished product. However, foam inserts can be used to added shipping box's strutural strength.

Foam and corrugated combo assemblies: Inner packaging provides added strength when ship products with multiple parts, products that come in sets, or products that require assembly. Having dividers and/or partitions inside the package keeps each individual piece secure and protected during loading, unloading and transportation.

Floater base/shock pallet cushioning systems: Pallet Cushion (đệm tấm gổ nâng hàng) provides fast, cost-effective and durable customized transportation damage solutions for industrial, commercial and military applications, and saves on costly transportation, providing maximum shock protection with minimal size and weight. Pallet Cushion is an Air-Dampened Cushions for reducing vibration and shock during transportation, which is specially designed to mount directly on a base of pallets, skids, crate, wooden case and container. Pallet Cushion provides protection and buffers against vibration and shock. Pallet Cushion is reusable which can be removed and installed on a new object easily and quickly. Spacer for Pallet Cushion can increase the height of the object, making the forklift and stacker more convenient to load and unload in the warehouse. By arranging a plurality of Pallet Cushions around one turn and mounting them on the bottom of the pallet, the cushioning effect is similar to an air-ride truck, which could save the cost of an expensive air-ride truck.

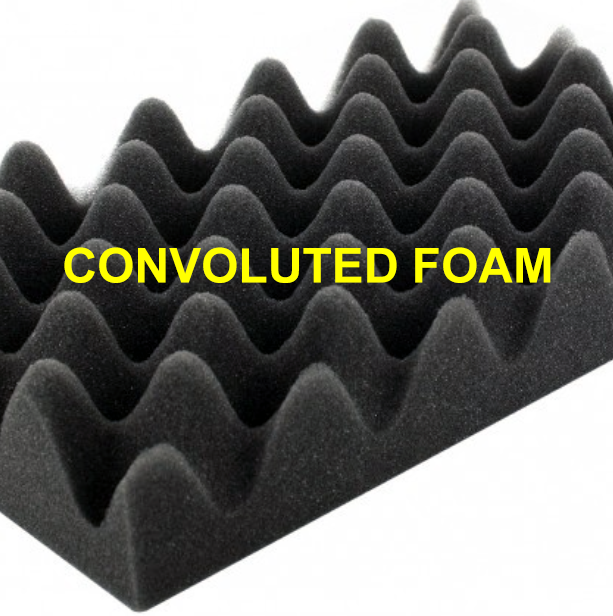

Convoluted Foam: A single sheet of convoluted foam (cao su xốp quấn lại với nhau) is effective for packaging several items of different sizes together. A sheet of convoluted foam may be used on the lid of an enclosure such as a hard case because it will put positive pressure and hold down force on the item, yet will give when it is closed and not put too much pressure on the item or seal.

Convoluted foam sheets, also known as “egg crate” are made by splitting a mechanically deformed foam sheet into two sheets that have peaks and valleys and nest together. The convoluter pushes the foam through rotating rollers with fingered pins, stretching and distorting the foam. When the blade passes through the distorted material it cuts a straight path, and when the foam rebounds back to its original sheet size, the egg crate pattern is the result.

Trays and inserts: Plastic insert trays display, protect, and organize products inside an outer container or carton. They are popular for retail display, product organization and orientation, and mailer inserts. Available in a variety of colors and finishes, plastic insert trays can enhance product branding. Dental, healthcare, cosmetic, and gift sets packaging use plastic insert trays to organize, display, protect, and secure multiple products inside an outer carton on container. Online-based mail delivery kits use plastic insert trays (mailer inserts) because they are easy to load, provide security and product protection in shipping; and, facilitate a positive unboxing experience. There is no assembly required, contrary to paperboard inserts. Lightweight and efficient use of materials. Anti-rotation features keep cylindrical products forward-facing. Finger access for ease of product removal.

Corner protectors/corner blocks

- Corner Block is used to keep corners and edges of wooden furniture intact during shipping. The 64A Corner Block measures 3 5/8″ in length, and the 77 Corner Block measures 1 1/4″, and the 81 Angle Block measures 2″(L) x 1″(W) . It is ideal for preventing damage to cabinetry, desks, and shelving units.

- Angle Block to keep angles and edges of wooden furniture intact during transportation. The 65 Angle Block measures 2″(L) x 1″(W) and is ideal for preventing damage to cabinetry, desks, and shelving units.

Heat-welded foam assemblies. PVC foam sheets and boards can benefit from the strong seams that radio frequency welding creates. The RF welding process is efficient and differs from other sealing methods in its use of radio frequency to generate heat that melts two or more surfaces together. The combination of electromagnetic energy and pressure through the use of upper and lower indexed dies temporarily melts the materials and permanently fuses them together. The seam is as strong as the original materials, forming a product that is resistant to wear and tear for years. Not all plastic materials are suitable for this process, other sealing methods including hot air sealing, hot wedge welding, solvent bonding, and commercial sewing.

REFERENCES AND RESOURCES

Flexible Packaging Learning Center. Find helpful articles, videos, guides, ebooks, infographics, calculators and cheat sheets to answer your questions about packaging machinery and flexible packaging materials including comparisons, costs, maintenance and more!

FOAMBOARDS offer the largest variety of foam board accessories including design and cutting tools, cornerforms and cornerfits, velcro products and a selection of safety straight edges, Olfa knives, Fletcher-Terry cutters, hot wire cutters and more!

IMPACT Mfg offer Plastic Based Packaging, Papper Based Packaging, Clamshell Packaging, Thermalform Trays, Flocked Trays, ESD Trays and Lids, Folding Cartons, Blister Packaging, Counter Top Display, Product Photography and more!

MIL-HDBK-304C U.S Department of Defense Handbook: Packaging Cushioning Design (01 June 1997). The information in this handbook applies chiefly to conventional cushioning materials. These materials include polyurethane foam, foamed polystyrene, and foamed polyethylene.

MPE Madison Polymeric Engineering, Inc. is a professional manufacturing company capable of providing customers with custom foam design & die cutting. Medical/Packaging Applications – Engineering Services – Design Services – Material Selections.

Nelson Container Packaging for Electronics & Corrugated Boxes for Electronics Equipment – Package Design – ISTA Testing – Protective Inner Packaging, Package Assembly and more.

NEFAB provides complete packaging solutions optimized to reduce total cost and environmental impact in your supply chain. & Packaging Solution – Packaging Products – ISTA Testing – Logistics Services and more.

Pelican Build to protect & Professional Cases – Protector Cases – Cargo Cases – Millitary, Goverment, Aviation, Aerospace and more.

Shorr Packaging Company Corrugated Products & Taps and Adhesives – Stretch Wrap Films – Protective Packaging Products – Flexible Packaging – Case Sealers – Case Erectors – Tray Formers – Baggers and Bagging Systems and many more packaging equipments.

Trans-Consolidated Distributors, Inc is one of the largest US distributors of industrial tape, stretch film, poly bags, and custom printed tapes, labels and more. We also carry 1000’s of other products to meet your packaging needs.

ULINE North America's leading distributor of shipping, packaging and industrial supplies. To meet customer needs, product lines have expanded to include retail, safety, material handling, industrial and packaging materials.

Zoro – Brass, Alloy Steel, Copper, Bronze – Foam and Foam Sheets, Cork, Fabric, Ceramic – Rubber, Plastics, Fiberglass, Wire Fabric, Aluminum, Stainless Steel, Carbon Steel, Shim and Shim Stock – Adhesive, Fasteners and Welding.